Trick Benefits of Using a High-Performance Heat Transfer Fluid

Why Warm Transfer Liquid Is Very Important for Optimizing Energy Transfer in Equipment

The role of warmth transfer liquids in maximizing power transfer is essential for attaining effective thermal monitoring throughout various industrial industries. These fluids facilitate seamless heat exchange, making sure processes run within optimal temperature level arrays and reducing the danger of getting too hot. Their choice, based on aspects like viscosity and thermal stability, straight influences the performance and sustainability of a system. The complexities of picking the appropriate liquid are typically taken too lightly. What are the essential factors to consider for this option, and exactly how do they impact both economic efficiency and environmental duty in commercial applications?

Duty in Thermal Administration

Warmth transfer liquids play a vital duty in thermal administration by successfully regulating temperatures in different commercial procedures and systems. These specialized fluids promote the transfer of warmth between various parts, making sure ideal operating conditions and avoiding overheating. By preserving specific temperature level control, warm transfer liquids enable sectors such as chemical manufacturing, oil and gas, and power generation to run safely and efficiently.

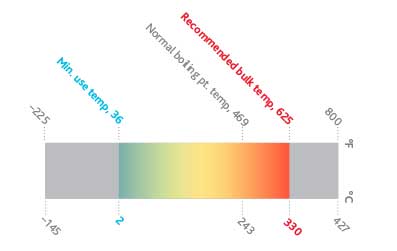

The choice of an ideal heat transfer liquid depends upon several variables, consisting of thermal stability, warm capability, and viscosity. High thermal security ensures that the liquid can endure severe temperatures without weakening, while a high warmth ability allows it to soak up and launch considerable amounts of warm - heat transfer fluid. Low thickness reduces the power required for pumping, adding to general system efficiency

In addition, heat transfer liquids are important in applications like refrigeration, where they help take in and dissipate heat during the cooling cycle. In solar thermal energy systems, these liquids capture and transport solar heat to generate power or offer warm water. Their flexibility to varied operating conditions and capacity to preserve constant thermal performance underscore their significance in commercial thermal management, helping with functional continuity and boosting safety and security measures.

Enhancing System Effectiveness

To take full advantage of the advantages of thermal management, enhancing system effectiveness with the calculated use warm transfer fluids is vital. These fluids play a crucial function in maximizing energy transfer by facilitating consistent thermal law, which consequently impacts the total performance and durability of systems. Reliable warmth transfer brings about lessened power losses, minimized functional expenses, and enhanced reliability of equipment. By preserving optimal temperature level levels, warm transfer fluids aid make certain that systems operate within their developed criteria, thus preventing getting too hot and minimizing the danger of element failing.

Kinds Of Heat Transfer Fluids

The variety of heat transfer fluids emphasizes their vital role in a her explanation series of commercial applications, each tailored to meet certain thermal monitoring needs. These liquids promote effective energy transfer and are picked based upon key residential or commercial properties such as thermal stability, viscosity, and heat capacity. The key kinds consist of water, glycol solutions, oils, and synthetics, each offering distinctive advantages.

Water is the most common warmth transfer tool due to its high specific warm capacity and reduced cost. Mineral oils are favored for their thermal security and non-corrosive nature, making them ideal for high-temperature applications.

These fluids make certain superior efficiency in systems where standard fluids may stop working. The selection of a warm transfer liquid is important, as it affects system performance, security, and durability.

Environmental and Economic Perks

Making use of the best warm transfer fluids supplies substantial environmental and financial advantages for industrial procedures. By picking fluids with premium thermal security and high heat capability, sectors can improve power efficiency, leading to lowered gas intake and lower greenhouse gas discharges. This adds to a smaller carbon footprint and lines up with worldwide sustainability objectives. Eco-friendly heat transfer liquids, typically biodegradable and non-toxic, lessen the risk of dirt and water contamination in the occasion of leakages or spills, thus safeguarding environments and abiding with rigid environmental laws.

Economically, the right warmth transfer liquid can dramatically decrease functional costs. Effective warmth transfer decreases power expense, leading to reduced utility expenses and boosted earnings. Liquids with extensive lifecycle performance reduce the regularity of replacements and maintenance, decreasing downtime and connected expenses. Spending in top notch liquids can additionally mitigate the threat of tools corrosion and failure, staying clear of costly repair services and expanding the life-span of essential facilities. In competitive markets, these financial savings and efficiencies supply a distinct benefit, enabling business to designate resources more efficiently and buy further advancement. Overall, the tactical use of optimal warm transfer liquids sustains sustainable financial growth and ecological stewardship.

Selecting the Right Liquid

Just how does one browse the complicated process of picking the best warmth transfer fluid for industrial applications? Thermal stability guarantees the liquid can endure high temperature levels without deteriorating, while compatibility stops rust or other harmful reactions with system elements.

Additionally, the liquid's warmth capability and thickness are vital. A high warm ability permits the liquid to absorb and transfer more power, boosting effectiveness. Ideal thickness guarantees marginal pump job and efficient warm transfer, particularly in differing temperature levels. Environmental and safety and security facets need to additionally belong to look at these guys the decision-making procedure. Non-toxic, naturally use this link degradable liquids lower ecological impact and abide by governing criteria, lessening liability threats.

Verdict

The tactical choice and application of warmth transfer liquids are fundamental to enhancing energy transfer throughout different systems. By making sure high thermal stability and ability, these liquids offer accurate temperature level control and improve total system effectiveness. This optimization adds to minimized functional expenses and lower greenhouse gas discharges, thus promoting sustainability. The selection of fluid, tailored to certain thickness and functional needs, is crucial for making the most of performance and achieving financial and environmental advantages in industrial procedures.